Is Hydrogen the Alternative To the Alternative?

Written by

Monday 13th May 2024

On the face of it, we seem to be wedded to electric batteries as the primary method of bringing carbon emissions down to net zero by 2050.

Even though the ban on selling new petrol or diesel cars and vans has been pushed back to 2035, the ZEV mandate, which sets out minimum levels of zero-emission vehicle sales between 2024 and 2030, means that most manufacturers remain committed to their original plans for switching over to battery electric vehicles.

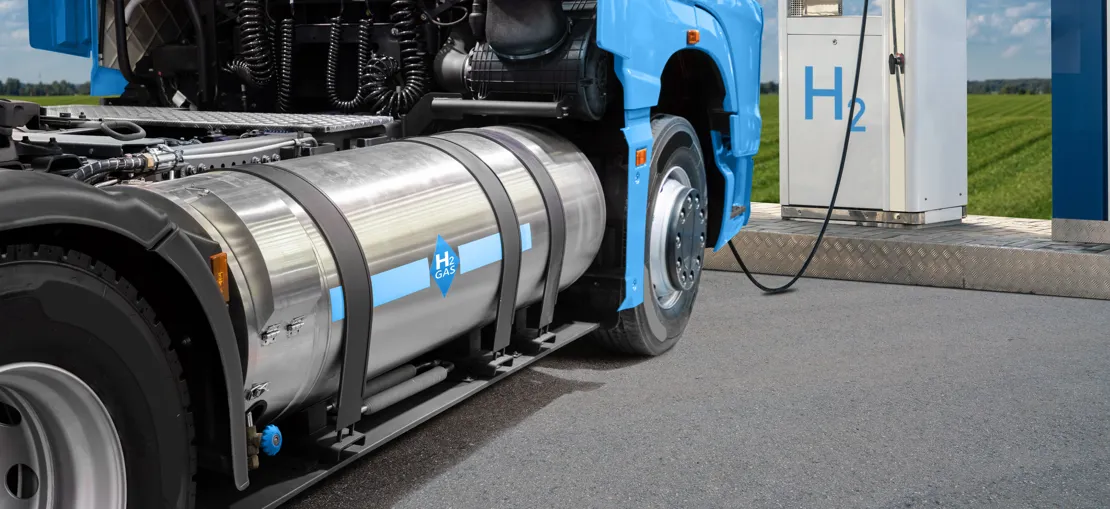

This begs the question, with the rate of EV adoption accelerating year on year, why are some fleet operators looking at hydrogen as an alternative to the alternative?

Hydrogen Fuel Cells

Although fuel cells are positioned as an alternative to batteries, we shouldn’t lose sight of the fact that we are still talking about electric vehicles — the key difference being the way that electricity is generated.

Although battery technology is still evolving, most EVs are powered by a lithium-ion battery and an inverter which converts the direct current (DC) in the battery to an alternating current (AC) that can power an electric motor and propel the vehicle forward.

A fuel cell is similar to a battery in that it has an anode, a cathode, and an electrolyte in the middle of the two. For many of us, this won’t mean a great deal but, in essence, it works like this.

Hydrogen from the vehicle’s onboard tank(s) flows into the anode and a catalyst then breaks the hydrogen molecules into protons and electrons using a process known as Hydrogen Oxidation Reaction (HOR).

The electrons travel through an external circuit, while the protons move through the electrolyte within the cell. As the electrons move about, they generate the electricity needed to power the vehicle’s motor and can also help charge an onboard battery that acts as a temporary buffer or energy storage device.

Although they take different routes, both electrons and protons end up at the cathode, where they mix with oxygen from the ambient air. Heat from the fuel cell stack converts this mixture into water vapour that can be easily discarded via a tailpipe or dedicated vent.

Hydrogen is the most abundant element in the universe, so there’s no real danger of running out. Getting it into the vehicle and manufacturing the fuel cells is another story. That said, although fuel cells have received the most publicity, they’re not the only way hydrogen can be used to power a vehicle.

Hydrogen Combustion

We all know that petrol and diesel vehicles generate environmentally damaging emissions, but we need to remember that it is the fuel source, not the combustion engine, that is the crux of the problem.

Hydrogen combustion engines work in a similar way to traditional ICE vehicles. Hydrogen is mixed with air and then compressed. This increases the pressure and temperature to a point where it can be ignited by a spark (much like a petrol car). Once ignited, the hydrogen reacts with oxygen and the rapid expansion of gases delivers the necessary force to drive the piston and power the vehicle.

In simple terms, hydrogen combustion engines convert the chemical energy of hydrogen into the mechanical energy needed to propel the car forward. So which is better, hydrogen combustion or hydrogen fuel cells?

Hydrogen Combustion Versus Fuel Cells

Combustion engines are generally less efficient than fuel cells because a significant amount of energy is lost as heat, noise, and friction between moving parts, such as pistons and crankshafts etc.

To put things into perspective, the energy efficiency of a hydrogen fuel cell ranges from 40% to 60%. Fossil fuel combustion engines operate at around half this level and although hydrogen combustion is more efficient than petrol or diesel, based on current technologies, it can’t yet reach the efficiency of a fuel cell.

Another difference can be seen in the emissions. While the primary output from a hydrogen combustion engine is water vapour, there can still be small amounts of nitrogen oxides (NOx) which arise due to the high temperatures involved in combustion. However, we shouldn’t fall into the trap of judging environmental credentials based on emissions alone.

Much like battery EVs, hydrogen fuel cell vehicles (HFCEVs) have a relatively small number of moving parts, which means there are fewer emissions involved in the manufacturing of components. However, fuel cells need platinum, which can be expensive and energy-intensive to extract and process.

There are other options, such as alkaline polymer electrolyte membrane fuel cells, which enable the use of nonprecious metal electrocatalysts, but durability and performance both take a hit.

You could argue that Hydrogen combustion engines offer a more familiar and potentially less expensive transition from fossil fuels, whereas fuel cells have the potential to deliver higher efficiency and lower harmful emissions. But it’s far from clear-cut.

How Green is Hydrogen Production?

The quick answer right now is not very. Most of the UK’s hydrogen is produced using fossil fuels and so, for hydrogen to be considered a green technology, something needs to change.

There are a few options on the table. The first is electrolysis (green hydrogen), which uses electricity to split water into hydrogen and oxygen. The environmental impact of this process primarily depends on how the electricity is generated. Currently, 45% of electricity generated in the UK comes from renewable sources — jumping to around 60% if we include low-carbon sources.

The second option is blue hydrogen, which uses a process called steam methane reforming (SMR) to combine natural gas with very hot steam. So far so good but, in addition to hydrogen, the SMR process generates quite a bit of carbon monoxide and ultimately carbon dioxide, which is just the thing we are trying to avoid in the first place. This means that, to make it a green energy, any carbon produced will need to be captured and potentially re-used by converting it into plastics, concrete, or biofuels etc. Currently, the Climate Change Committee (CCC) estimates that 90%+ can be captured — but this is just an estimate.

Nuclear will also have a role to play and the Nuclear Industry Council (NIC) estimates it could produce as much as 75TWh of green hydrogen by 2050 using various forms of electrolysis and small modular reactor technologies. This could include splitting hydrogen and oxygen without the use of electricity.

In reality, it will be a combination of these, and as yet untested solutions, that will form the future of clean hydrogen production.

Hydrogen Infrastructure and Capacity

The UK has a stated ambition of delivering 5GW of hydrogen production capacity by 2030. To put this into context, that’s the hydrogen equivalent of the gas consumed annually by 3 million UK households. As can be seen, we are a long way from hydrogen being a viable alternative.

Another challenge is that of infrastructure. In 2022, there were 15 hydrogen fuel stations in the UK. Rather than growing, this number fell to just 11 by March 2023. In comparison, there are more than 31,000 locations where you can charge up a battery EV.

Hydrogen fuel stations are expensive to build and operate, costing anything up to £2m, with annual running costs that are 10-15 times that of an EV charging station (on a per kW basis).

Building a viable hydrogen infrastructure will require sizeable investment from the private sector without the prospect of breaking even for many years to come. Companies such as Shell say they will continue to develop a hydrogen refuelling infrastructure to meet the needs of customers. This mirrors the approach of many private sector businesses — and for good reason. The private sector depends on market demand to justify investment but, without an infrastructure, there will be little in the way of demand. Overcoming this ‘chicken and egg’ challenge requires a long-term vision.

The scale of the challenge cannot be overestimated. Mass adoption of hydrogen vehicles will require a UK-wide transport and storage infrastructure so that hydrogen is accessible where end-users need it to be. Production units also need to be built and integrated with Carbon Capture, Usage and Storage (CCUS) facilities, as well as gas and electricity networks.

Of course, some hydrogen vehicles are already in use, including buses in Aberdeen, Birmingham, London, Belfast, and Dublin. Generally speaking, hydrogen vehicle operators can compensate for the lack of infrastructure through ‘bunkering’ which, in simple terms, means creating an on-site hydrogen storage facility supported by strategically positioned refuelling stations. In theory, hydrogen could be produced onsite, but it’s generally easier to partner with a hydrogen supplier with the necessary infrastructure already in place.

Bunkering only really works for clearly defined applications and transport routes and even then, the space, investment, and operational resources needed to build and maintain the facility make it a non-starter for most fleets.

What Does it Cost to Run a Hydrogen Vehicle?

Any new technology, with a limited level of usage and supply options, will always be expensive. There are so many variables involved that it is difficult to be too prescriptive about the real-world costs, but one way to explore the cost is to look at the Levelized Cost of Hydrogen (LCOH), which calculates the average cost per unit of hydrogen produced over the lifetime of a hydrogen production facility. Research shows that the LCOH for a blue hydrogen facility is likely to be around £1.90–2.80 per kg, with almost all the carbon emissions being captured.

In terms of energy, one kg of hydrogen roughly equates to 3.8 litres of petrol. Using average petrol prices from December 2023, we can see a comparative cost of £5.48 for petrol and £5.77 for diesel. Of course, the true cost of fuel depends on the efficiency of the vehicle's engine or fuel cell, market conditions and more, but it shows the possibilities.

In this example, we are comparing hydrogen with fossil fuels, rather than a battery electric vehicle. A similar process of comparing equivalent units of energy would also make hydrogen cheaper than battery electric vehicles. That said, we also need to factor in how the competing technologies develop and the level of supporting infrastructure, together with vehicle efficiency rates, total cost of ownership and the actual existence of vehicles that will do the job.

When Will Hydrogen Be Ready For Mass Adoption?

Tangible progress in the development of a viable hydrogen economy will require collaboration, innovation, and government support, but momentum is growing.

The Hydrogen Council includes nearly 150 international companies such as Audi, BMW, Honda, and Toyota, along with BP, Shell, Michelin, and Microsoft. Its stated ambition is to identify and remove barriers to hydrogen as a vital component in decarbonising energy by fostering collaboration across the supply chain.

Clearly, there is a long road ahead, but there is also a strong commitment to make it happen. Hydrogen is not the only solution, but then again, neither are batteries. Decarbonising the UK, and in particular our transport networks, requires the development and adoption of technologies that complement, rather than compete with each other. Battery electric vehicles are a technology that works right now for a large percentage of business fleet operators, but the long-term solution will undoubtedly include hydrogen.